6 Solutions for Undercut Features in Injection Molding: Technical Analysis

Injection molding undercuts are recessed or protruding features on a part that prevent or complicate ejection from a straight-pull mold. Al...

Top 10 New Technologies in Plastic Injection Molding in 2025

As the plastics industry races toward greater efficiency, quality and sustainability, the new technology in plastic injection molding is re...

What is Mold Making? Process, Development and Mold Manufacturing

Mold making is the industrial process of designing and fabricating a tailored mold (or “tooling”) that shapes raw material into a desired pa...

Multi Component Injection Molding for Complex Part Designs

Multi component injection molding uses specialized multi-shot molding machines with two or more injection units to combine different materia...

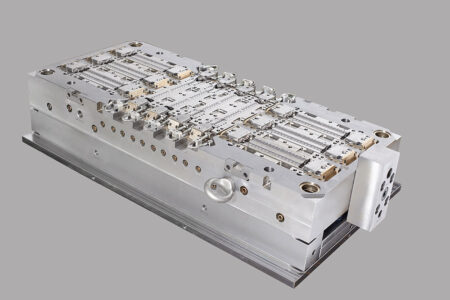

Precision Mold Manufacturing for Automotive Components: A Comprehensive Guide

Introduction The automotive industry is undergoing a significant transformation, driven by the demand for enhanced safety, performance, and...

How to Choose a Reliable Dashboard Molding Manufacturer

Introduction Automotive dashboard molding is a critical process that shapes the interface between driver and vehicle. A well‑molded dashboar...

Why Choose China Automotive Injection Molding Service

China Automotive Injection Molding Manufacturer – Huazhi As a China automotive custom injection and die casting mold manufactu...

Plastic Injection Mold Life Expectancy for Automotive Parts Manufacturing: Key Factors and Best Practices

Introduction In the highly competitive automotive industry, the demand for mass production of high-precision plastic parts is relentless. M...

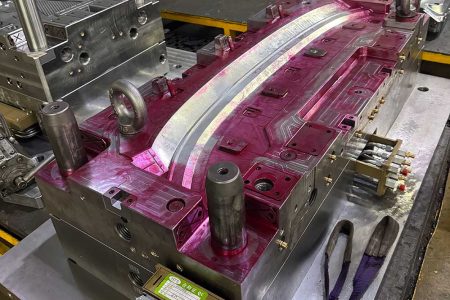

What Is Car Window Trim Moulding? A Complete Guide for Automotive Parts Buyers and Engineers

Introduction Why Car Window Trim Moulding MattersCar window trim moulding plays an outsized role in the look, feel, and performance of ever...

Top 5 Car Bumper Plastic Material Choices for Injection Molding

Introduction: In the automotive industry, car bumpers are essential components that provide safety and aesthetic appeal. The choice of car ...

Two Color Plastic Injection Molding vs. Overmolding: What Are the Differences?

Introduction Injection molding is a cornerstone of modern manufacturing, particularly when it comes to producing high-quality, durable plas...

15 Most Common Injection Molded Plastic Materials: A Guide to Chemical Resistance and Durability

Introduction Injection molding has become a standard manufacturing process for producing high-quality plastic components. In today’s compet...