Trusted Worldwide

Mold Customization Service

With 20+ years of experience, we are a global mold manufacturing expert,

providing you with a one-stop solution from design to delivery.

Injection Mold Design Experts | Custom High-Precision Mold Solutions

Achieve precision and performance with injection mold design tailored to your needs. Over 20 years of expertise in delivering custom molds.

Precision Mold Customization

●Multi-field coverage:

supports mold customization in various industries such as automobiles, home appliances, office supplies, medical devices, etc.

●Precision design:

Provide free manufacturing design (DFM) analysis to optimize product structure and mold process to ensure molding accuracy.

●Quick response:

Relying on rich experience and perfect processes, the development cycle is greatly shortened and efficiency is improved.

●Strict quality control:

Adopt 120+ advanced equipment and mature quality management system to ensure stable and reliable mold quality.

Mould industry application

Automotive industry molds

Complex and large parts such as bumpers, dashboards, lamps, etc.

Household appliance molds

Housings, panels, high-gloss parts and internal parts.

Medical device molds

Precision housings, consumables, instrument components and other high-demand products.

Industrial equipment molds

Small precision parts such as mobile phone cases, connectors, internal brackets, etc.

Consumer electronics molds

Small precision parts such as mobile phone cases, connectors, internal brackets, etc.

Packaging industry molds

Plastic containers and lids for food, beverage and other industries.

Highly Efficient Injection Mold Design Solutions

HUAZHI’s mold design service focuses on customization, high precision and efficient collaboration, providing customers with mold solutions that optimize production costs and improve efficiency. We are committed to empowering each project and achieving seamless transformation from design to finished product!

●Full process support: Provide end-to-end professional services from demand analysis to design delivery.

●High-precision solutions: Ensure accurate and efficient mold design through advanced tools and rich experience.

●Customer collaboration: Real-time communication and feedback to ensure that the design solution fully meets customer expectations.

CNC machining center

Accuracy up to ±0.005mm, used for complex structure processing.

EDM electric spark forming machine

Suitable for complex curved surface processing of mold cavity.

Wire cutting machine

Achieve high-precision mold parting surface and insert processing.

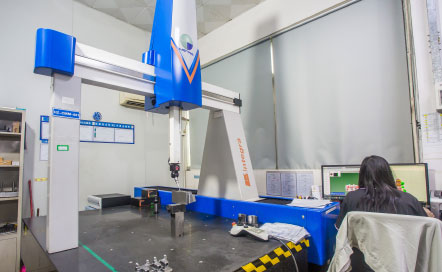

Coordinate Measuring Machine (CMM)

Measure the mold size accuracy to ensure it meets customer requirements.

Mold assembly center

Use professional fixtures and hydraulic lifting platforms to ensure accurate assembly of each component

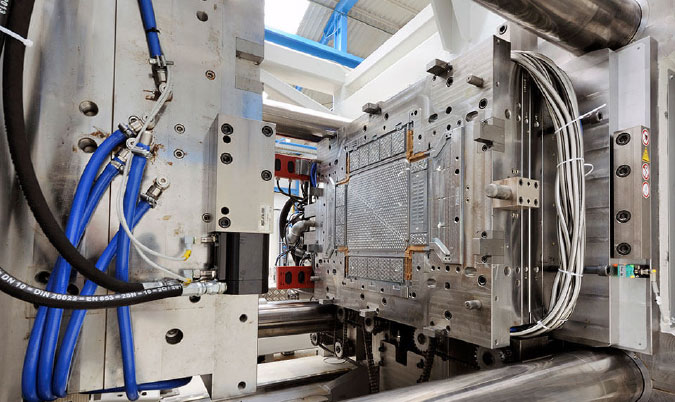

Injection molding center

Ensure smooth connection between mold performance verification and production

Injection molding mold design process

HUAZHI molds have efficient collaboration throughout the process, with a senior team and strict quality control system to ensure mold accuracy and stability.

Ensure the rapid delivery of high-quality molds.

1.Demand analysis

Communicate in depth to clarify product requirements and production goals, conduct functional analysis, material selection and technical requirements evaluation.

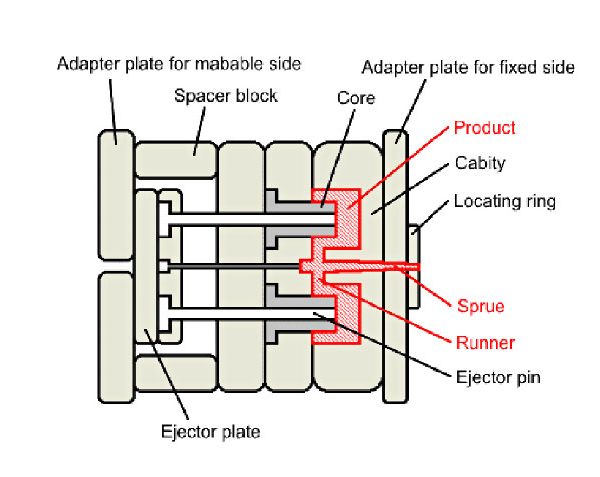

2.Mold design

Provide free manufacturing design (DFM) analysis to optimize key structures such as gates, cooling channels, and parting surfaces to ensure efficient and reliable mold design.

3.Raw materials and parts preparation

Select high-quality mold steel materials (such as P20, 718, NAK80, etc.) according to design requirements. Process mold parts, including cores, cavities, gate components, etc.

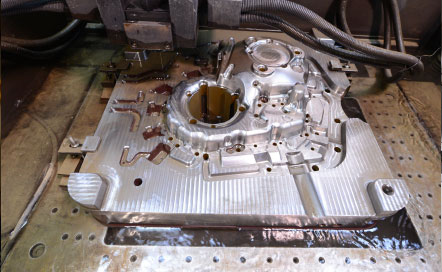

4.Processing and manufacturing

Use precision equipment to perform rough processing, fine processing and heat treatment on the mold to ensure mold strength and durability. Key processes include CNC machining, EDM, wire cutting, drilling, grinding, etc.

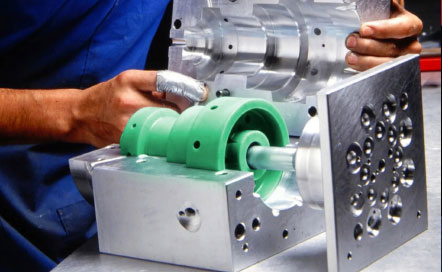

5.Assembly and debugging

Assemble the components into a complete mold. Carry out injection molding trial mold (T1) debugging, check mold performance and product quality, and optimize parameters.

6.Quality inspection and delivery maintenance

Carry out comprehensive inspection of the mold, including dimensional accuracy, hardness, finish, flow channel uniformity, etc., to ensure that it meets customer needs. Complete final packaging and delivery, and provide subsequent technical support and maintenance services.

We offer a variety of mold types

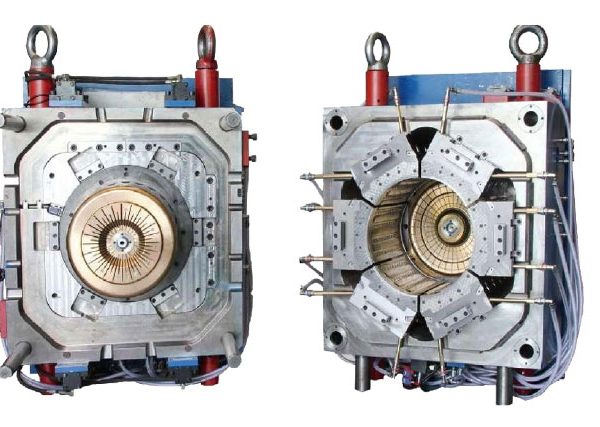

Injection mold design

Used for molding plastic products, widely used in automobiles, home appliances, medical and consumer electronics, etc., suitable for mass production of plastic parts with complex structures.

Die-casting molds

Used for high-pressure injection molding of aluminum, magnesium, zinc and other alloys, mainly used in automotive parts, electronic housings and industrial equipment, with high precision and high strength advantages.

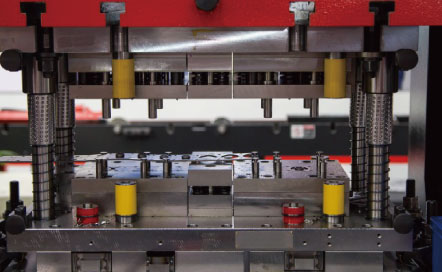

Stamping molds

Used for cutting, bending or molding metal sheets, suitable for manufacturing metal parts such as automotive sheet metal parts, electrical housings, etc., with high efficiency and suitable for large-scale production.

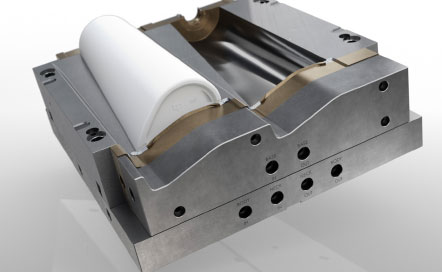

Blow molding molds

Used for the production of hollow plastic products such as bottles, containers and pipes, commonly used in the packaging industry and daily consumer goods.

Investment casting molds

We can make low-cost investment casting molds by 3D printing wax molds and wrapping them with ceramics. Ceramic molds can then be used to make metal castings made of metals such as aluminum, zinc, magnesium, stainless steel, etc.

Extrusion molds

Used for the production of continuous profiles such as pipes, profiles and cable sheaths, widely used in construction, communications and industrial pipelines.

International brand mold cooperation

HUAZHI provides customers with precise mold solutions with professional technology and affordable prices,

helping global partners achieve success.