How to Choose the Right Die Casting Mold Supplier for Your Project

Choosing a die casting mold supplier is a strategic decision that can make or break your manufacturing timeline, product quality, and profitability. From initial design to after-sales maintenance, a top-tier supplier serves not just as a vendor but as a partner—infusing technical expertise, process optimizations, and supply chain resilience into your project. Below is a comprehensive guide to help procurement teams and engineers select the ideal die-casting mold supplier for automotive, appliance, electronics, and other precision-driven components.

Understanding the Role of a Die Casting Mold Supplier

A die casting mold supplier does much more than simply fabricate steel blocks. Their full scope of service typically includes:

-

Design Collaboration: Utilizing CAD/CAM and mold flow analysis tools, they translate your part drawings into optimized mold designs. This early DFM (Design for Manufacturability) phase identifies potential fill imbalances, air traps, and hot spots, preventing costly redesigns later.

-

Material Expertise: Suppliers recommend the appropriate tool steel grade—P20 for general-purpose molds, H13 for high-volume automotive parts, or S136 for corrosion-resistant applications—and identify when advanced surface treatments like PVD coatings or nitriding are needed to extend mold life.

-

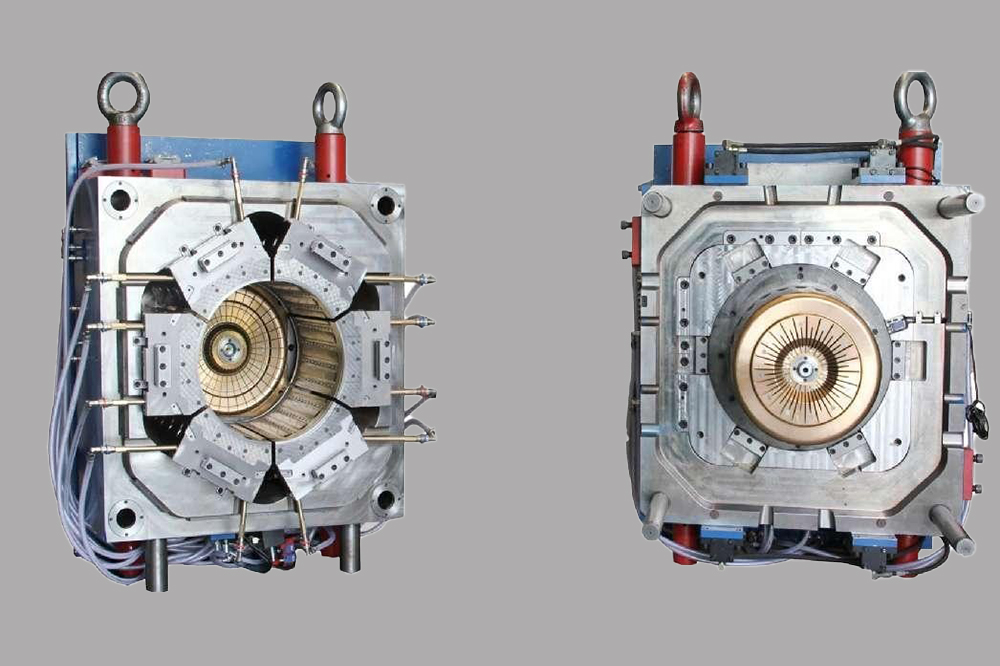

Precision Machining & Polishing: With a combination of 5-axis CNC milling, wire EDM, and precision surface grinding, they achieve tight tolerances (often ±0.02 mm or better) and surface finishes (Ra 0.4–1.2 μm) essential for beauty panels, lens molds, or fluid-handling parts.

-

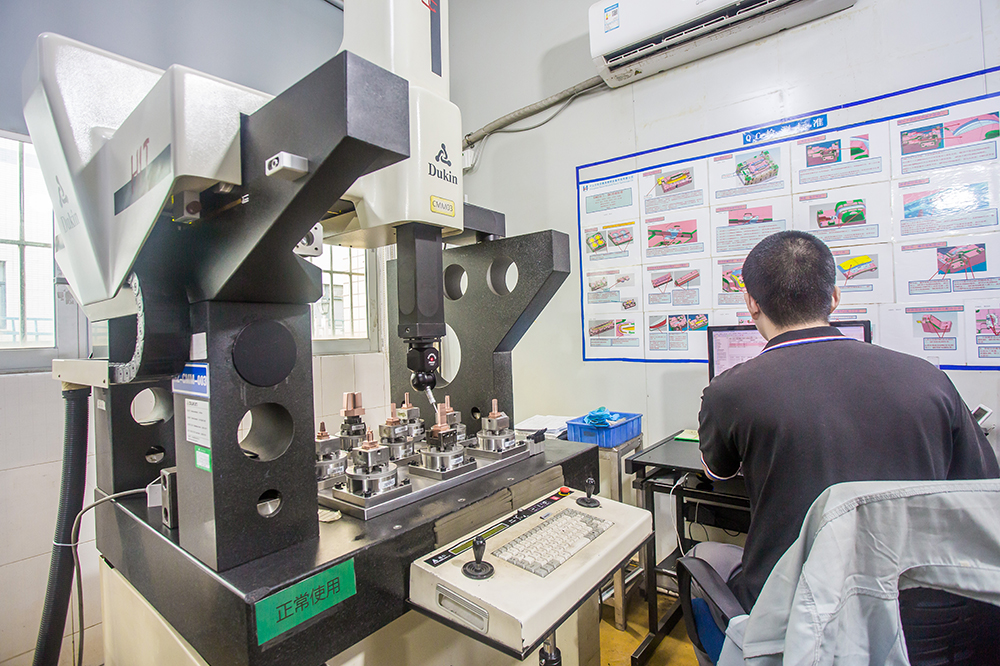

Quality Validation: In-house CMM (Coordinate Measuring Machine) inspections, block-by-block material certification, and pilot runs ensure each mold meets PPAP (Production Part Approval Process) level 3 or higher, safeguarding against defects in mass production.

-

Lifecycle Support: Beyond initial delivery, top suppliers provide scheduled maintenance, repair services, and upgrade options (e.g., adding slides, conformal cooling, or hot-runner conversions) to maximize tool uptime over hundreds of thousands—or even millions—of cycles.

By understanding this holistic role, you can evaluate suppliers not only on price but on the depth of capabilities they bring to your project.

Key Selection Criteria for Die Casting Mold Suppliers

When narrowing your list of potential die casting mold suppliers, consider these critical factors:

-

Technical Proficiency

-

Engineering Team: Look for a robust in-house design staff skilled in DFMEA, mold-flow simulation, and finite element analysis to optimize mold geometry for minimal thermal stress and uniform fill.

-

Prototyping Capabilities: Rapid tooling via aluminum or epoxy molds can validate form, fit, and function within days, reducing risk before committing to full steel mold builds.

-

-

Quality Systems & Certifications

-

IATF 16949 / ISO 9001: Mandatory for automotive applications, these certifications guarantee rigorous process controls and continuous improvement practices.

-

Statistical Process Control (SPC): Weekly or even daily SPC reports on critical dimensions demonstrate a supplier’s commitment to consistency and early detection of process drift.

-

-

Production Infrastructure

-

Machine Fleet: A diverse set of injection presses or casting machines (from 250 to 2,000+ tons) ensures flexibility to handle small, intricate molds or large, multi-cavity tools.

-

Toolroom Capacity: Facilities with integrated toolrooms can iterate faster, with machining, EDM, and polishing shops on the same campus, eliminating shipping delays and coordination headaches.

-

-

Financial Stability & Scalability

-

Order Volume Flexibility: Verify the supplier’s ability to scale from initial prototyping volumes (hundreds of parts) to long-run production (millions of parts) without sacrificing quality or delivery reliability.

-

Transparent Quoting: Detailed cost breakdowns—covering raw materials, machining hours, finishing operations, and contingencies—help you compare bids with confidence and avoid hidden change-order fees.

-

-

Geographic Reach & Logistics

-

Global Warehousing: Local inventory hubs in North America or Europe can offer JIT (Just-In-Time) replenishment programs, mitigating freight delays and safeguarding your production schedules.

-

Incoterm Options: A supplier knowledgeable in FOB, CIF, or DDP shipping ensures clarity around cost vs. risk, enabling you to choose the best arrangement for your supply chain.

-

By rigorously scoring suppliers against these criteria, you’ll narrow down to those capable of meeting your project’s technical, financial, and logistical demands.

The Die Casting Mold Supplier Evaluation & Onboarding Process

A structured onboarding process minimizes surprises and aligns expectations from day one:

-

Prequalification

-

Issue an RFI (Request for Information) to gather high-level data: certifications, equipment list, core expertise, and established markets.

-

Conduct desktop reviews of past case studies, testimonials, and product catalogs to ensure industry alignment.

-

-

Technical Audit & Factory Visit

-

Tour toolrooms, machining centers, and molding floors to verify equipment age, maintenance practices, and workforce skills.

-

Interview the engineering and quality teams to assess communication clarity, problem-solving approaches, and cultural fit.

-

-

Prototype Run

-

Commission a small, inexpensive aluminum soft mold or 3D-printed insert to validate mold concept, flow balance, and surface finish before full steel mold commitment.

-

-

Pilot Production & Quality Sign-Off

-

Approve the final steel mold through trial runs, measuring key dimensions, cycle times, and cosmetic quality.

-

Sign off on PPAP documents and sample parts before releasing the tool for full production.

-

-

Contract & SLAs

-

Finalize agreements on lead times, acceptance criteria, maintenance schedules, and performance bonds.

-

Establish agreed KPIs (On-Time Delivery, Reject Rate, Tool Life) with clear remedies for underperformance.

-

This rigorous process ensures that both parties agree on technical standards, timelines, and commercial terms, paving the way for a smooth long-term partnership.

Why Choose Huazhi as Your Die Casting Mold Supplier

When you partner with Huazhi, you tap into:

-

Comprehensive Expertise: 180+ engineers and technicians, 8,000+ molds delivered, from single-cavity prototypes to 25-ton multi-cavity tools.

-

Advanced Infrastructure: State-of-the-art CNC, EDM, PVD coating, in-house soft tooling, and rapid prototyping labs—enabling end-to-end mold development under one roof.

-

Automotive Focus: TS 16949–certified processes, dedicated automotive divisions, and a zero-defect recall history on safety-critical parts.

-

Global Footprint: Long-standing partnerships with OEMs and Tier 1 suppliers in the US, Japan, Germany, and Canada—backed by multilingual support, local warehousing, and flexible Incoterms.

-

Innovation & Speed: Continuous investment in Industry 4.0, IoT-enabled monitoring, and digital twin simulations reduces your time-to-market by up to 30%.

Huazhi doesn’t just supply molds—we engineer solutions that accelerate your product launches, optimize long-term costs, and guarantee consistent quality across millions of parts.

Conclusion

Selecting the right die casting mold supplier is more than a purchase—it’s a collaboration that shapes your product’s success, cost efficiency, and time to market. With Huazhi’s comprehensive capabilities, automotive focus, and proven track record, you gain a partner dedicated to engineering excellence and on-time delivery.

📞 Ready to elevate your molding projects? Contact Huazhi today for a free consultation and customized quotation—let’s build your next success together!

Frequently Asked Questions

Q1: What is the typical lead time for a die casting mold?

Lead times vary by complexity: standard automotive molds average 5-6 weeks; expedited projects can be delivered in 3-4 weeks using rapid tooling techniques.

Q2: How do you ensure mold longevity and performance?

We select appropriate tool steels (H13, S136), apply advanced surface treatments (PVD, nitriding), and execute preventive maintenance plans—achieving tool life in excess of 1 million cycles for high-volume applications.

Q3: Can you handle multi-cavity and large molds?

Yes, our production capacity includes single-cavity, multi-cavity (up to 64-cavity), and large structural molds—supported by presses up to 2,000+ tons.

Q4: What support do you offer after mold delivery?

Huazhi provides scheduled maintenance, on-site repairs, spare part kits, and performance monitoring dashboards—keeping your tool running at peak efficiency.

Q5: How do you manage quality control?

We employ in-process SPC, block-by-block hardness and composition testing, CMM inspections, and full PPAP documentation, ensuring each batch meets your exact specifications.