What is Mold Making? Process, Development and Mold Manufacturing

Mold making is the industrial process of designing and fabricating a tailored mold (or “tooling”) that shapes raw material into a desired part. A mold is a precision cavity into which molten material – such as plastic, metal, rubber or silicone – is injected or poured to reproduce the part’s geometry. In other words, mold making creates a durable “negative” of the part. When injected or cast repeatedly, this mold yields identical parts in high volumes with strict tolerances.

A custom mold is engineered specifically for one client’s part design and production needs, often incorporating specialized gating, cooling and ejection features. For example, a plastic injection mold is typically made from hardened steel or aluminum and precisely machined so that each injection shot produces a finished plastic component. Custom molds allow manufacturers to achieve consistent quality and efficiency; they minimize waste and cycle time, and they enable innovation (e.g. complex geometries or multi-material parts) at scale.

Custom mold making is vital in industries like automotive, aerospace, medical, and consumer electronics, where precision and repeatability are critical. It differs from simple “mold-making” (crafting rubber or silicone molds by hand) in that it uses advanced design and machining technologies to create production-grade metal molds.

For example, after a mold is designed in CAD/CAM software and optimized by simulation, manufacturers use CNC machining and electrical discharge machining (EDM) to carve the mold block out of tool steel. The finished metal mold is then fitted with cooling channels and ejector pins so it can be mounted in an injection press. In this way, custom mold making bridges prototype and mass production – it ensures high-quality, precise parts for large-scale manufacturing.

History of Custom Mold Making

Mold making has ancient roots but really accelerated during the Industrial Age. Archeological evidence shows that the concept of molds dates back thousands of years: as early as 3200 B.C., Mesopotamians used clay and stone molds to cast copper tools. In ancient Egypt and Greece, craftsmen used reusable molds for metalwork and pottery. The Renaissance and early modern period saw advances in bronze and metal casting techniques, but the real revolution came in the 19th and 20th centuries with plastics and automation.

In 1872, John and Isaiah Hyatt invented the first plastic injection molding machine. Initially crude, this device led to new consumer products (combs, buttons) made from early plastics. By the early 1900s, safer plastic materials like cellulose acetate were developed. The 1930s brought breakthrough polymers (polyolefins, polystyrene, PVC). World War II dramatically increased demand for molded plastics (and replacement materials for scarce rubber/metal). Post-war, mass-production plastics became ubiquitous; inventor James Hendry’s 1946 screw-injection system greatly improved mold quality.

Late 20th-century mold making was transformed by digital technologies. The introduction of CNC (computer numerical control) machining in the 1950s–60s enabled automated, high-precision shaping of steel mold blocks. Wire EDM machines emerged in the late 1960s to cut hardened steel with extreme accuracy. By the 1970s and beyond, multi-axis CNC mills, CAD/CAM design tools, and simulation software allowed extremely complex molds and rapid iterations.

For example, by the 1990s aluminum molds became popular as a faster, lower-cost alternative to steel for prototypes. Today, leading mold makers use 5-axis CNC, mold flow analysis and robotics – all grounded in knowledge from decades of R&D. In summary, mold making evolved from simple sand and plaster molds to sophisticated custom metal tooling, reflecting the needs of modern manufacturing.

How Does Custom Mold Making Work?

The custom mold making process typically follows these key stages:

-

Design & Engineering: First, engineers use CAD software to create a detailed 3D model of the mold based on the part’s geometry. Simulation tools (e.g. mold flow or FEA) analyze filling, cooling, and stresses to optimize the design. Critical features like gates, runners, vents, and ejector pin locations are planned at this stage.For complex or legacy parts, reverse-engineering (3D scanning an existing part and creating a CAD model) may be used. Key considerations are incorporated: draft angles (to aid ejection), uniform wall thickness, and suitable shrink allowances. This CAD data is used for DFM (Design for Manufacturability) analysis, and top mold makers often provide free DFM feedback to avoid costly revisions.

-

Prototyping: Before committing to a hardened steel tool, some projects use a prototype or soft mold. For example, a rapid aluminum or epoxy prototype mold can be produced (or even a 3D-printed insert) to validate the part design. Advanced Prototype Molding (APM) and others offer such short-run molds to test fit, function and aesthetics. In this way, any issues can be caught early.

-

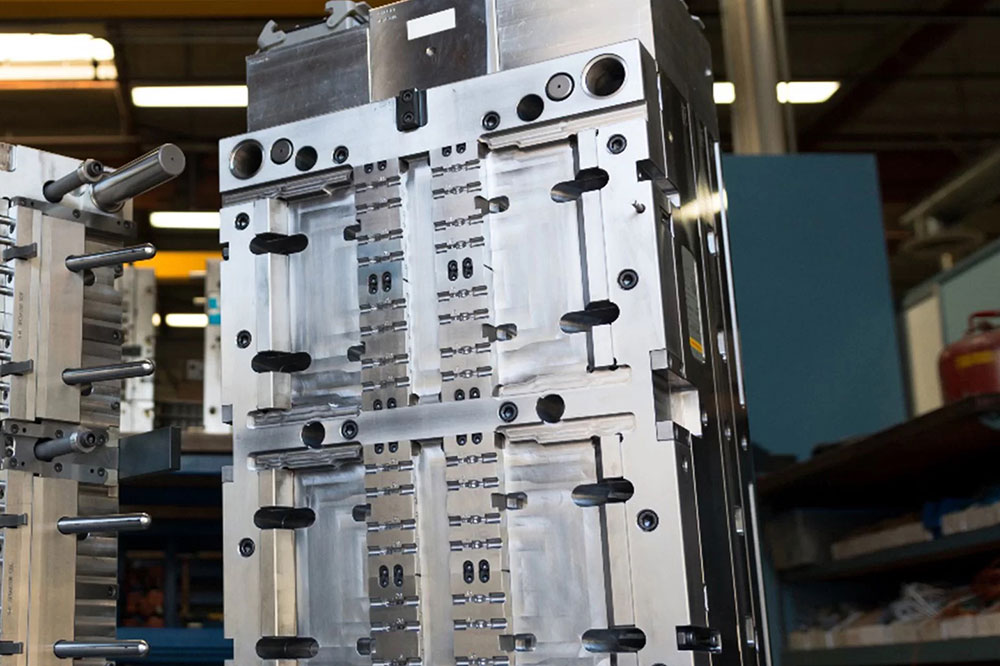

Mold Fabrication: Next, the bulk machining begins. Raw mold plates (steel or aluminum) are milled and turned on CNC machines into rough cavity and core shapes. Multi-axis CNC milling carves out most of the material (see photo below). For extremely hard sections or complex undercuts, Electrical Discharge Machining (EDM) is used to erode steel precisely. Modern mold fabrication often flows like this:

-

CNC Milling: Large 3-, 4- or 5-axis milling centers machine the cavity and core blocks to near-final shape.

-

CNC Turning: If cylindrical features are needed (e.g. a mold for a round container), CNC lathes turn the steel to form the basic shape.

-

Wire EDM: A thin wire (usually brass) cuts precise, complex profiles or separate molds from a single block.

-

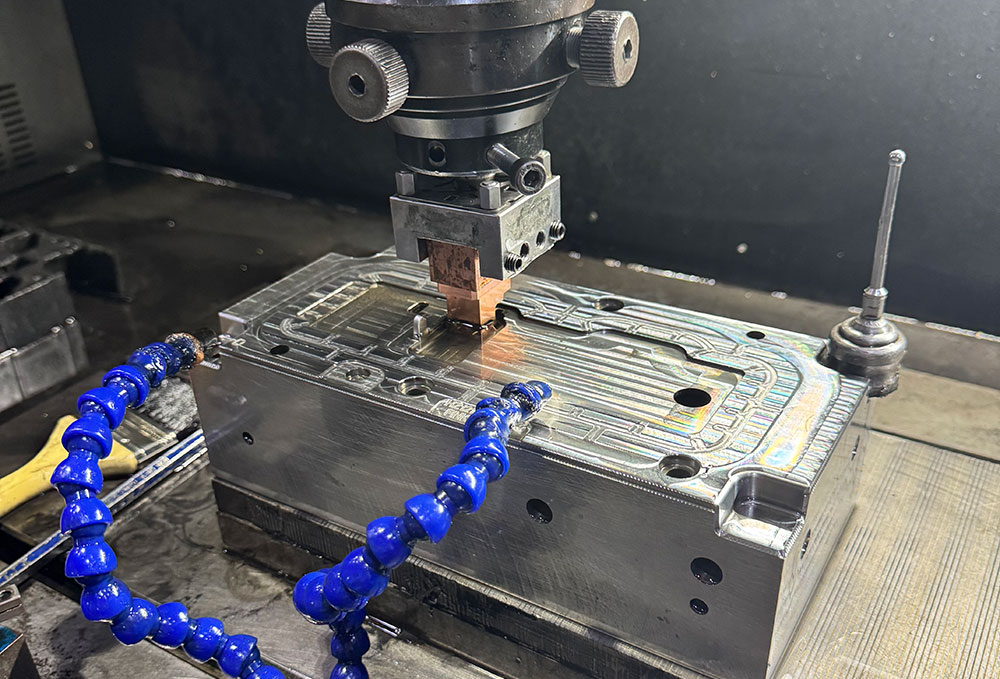

Ram (Sinker) EDM: Graphite or copper electrodes shaped like the cavity are plunged into hardened steel with electrical discharges to form intricate details and sharp corners.

-

CNC Grinding: High-precision grinders refine flat surfaces or cylindrical parts to tight tolerances and smooth finishes.

-

After machining, mold components may be heat-treated (especially if steel hardness needs increasing), then hand-finished. Skilled technicians polish the cavity surfaces to meet surface finish requirements (mirror polish for optical parts, textured for matte finishes). Mold plates are then fitted with hardware: inserting ejector pins, cooling lines (water or oil channels), guide pillars and bushings, springs, and any sliders or lifters needed for undercuts. The two halves (core and cavity) are aligned and secured in a mold base.

-

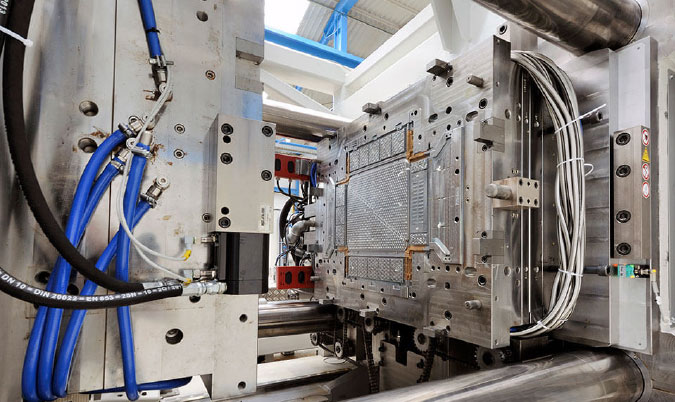

Trial and Adjustment: With the mold assembled, it is installed in a molding press for a trial run. The first test shots (often called T1 samples) are molded. Parts are inspected for defects, dimensional accuracy and fit. If issues are found (e.g. short shots, flash or part warping), the mold or process is adjusted: gate size/location may be modified, vents added, cooling changed, or machining tweaked. Most reputable mold makers include a couple of trial iterations to ensure the mold meets specifications.

-

Production: Once validated, the mold is ready for full-scale production use in injection molding, die casting or other forming equipment. In operation, the mold will cycle: clamping, injection, cooling, and ejection of parts. Throughout, the mold maker’s design decisions (cooling layout, ejection scheme, etc.) ensure stable, high-yield production. Experienced operators fine-tune the injection machine parameters to maximize part quality and minimize cycle time.

Each project’s workflow can vary, but modern custom mold making always integrates digital design, precision machining, and rigorous quality checks to deliver a mold that produces parts reliably and consistently.

Required Equipment and Machines for Custom Mold Making

Custom mold makers rely on specialized equipment to turn designs into reality. Key machines and tools include:

-

CNC Machining Centers: Multi-axis CNC mills (3-, 4- or 5-axis) are the workhorses of mold making. They remove material from steel or aluminum blocks according to CAM-generated toolpaths. High-speed, high-precision CNC mills can produce complex mold cavities and cores. CNC lathes are also used for cylindrical mold components (e.g. round inserts).

-

Electrical Discharge Machines (EDM): As noted by industry experts, EDM is “a critical component in the mold-making process” for creating detailed cavities in hardened steel. Two types are common: Ram (sinker) EDM, which uses a custom-shaped electrode plunged into the workpiece to burn the cavity shape; and Wire EDM, which uses a continuously fed wire to cut precise contours or parts off from a block. EDM excels at hard steels and intricate features that are difficult for cutting tools.

-

CNC Grinding Machines: Surface and cylindrical grinders finish critical faces to tight tolerances. For example, surface grinders ensure mold base plates and cavity surfaces are perfectly flat. Grinding is often used near the end of mold fabrication to achieve high-quality surface finishes and exact dimensions.

-

Polishing Equipment: After machining, hand or mechanical polishing tools (diamond belts, burrs, buffing wheels) refine the cavity surface to the required finish level, eliminating tool marks. This step is essential for clarity or matte effects on final parts.

-

Coordinate Measuring Machine (CMM): Precision measuring machines verify that the machined mold components match the CAD design and tolerances. A CMM probe can measure critical features of the cavity/core to ensure accuracy before assembly.

-

Mold Assembly Tools: This includes presses, hydraulic rigs, and fixtures for assembling mold halves, inserting pins and bushings, and mounting cooling line fittings. Threading taps and screwdrivers are needed for installing ejector pins, screws and water fittings.

-

Heat-Treatment Furnaces: Many steels require heat treatment (like quenching and tempering) to reach optimal hardness. Furnaces for carburizing, nitriding or stress-relief are often part of a mold shop’s equipment.

-

Auxiliary Tools: EDM drilling machines (for making ejector pin holes), laser engravers (for part numbers or logos), and even 3D printers (for quick resin prototypes or sand cores) may be used.

-

Injection Molding Machine: While not directly part of mold fabrication, access to a molding press is needed for trial injections (T1 sampling). A test press (or rental of a client’s press) is used to validate molds, as industrial sources note the importance of trial runs in mold making.

These machines work in concert: design data (from CAD/CAM) is fed into CNC and EDM equipment, shaping the mold block with micron accuracy. According to industry guides, “CNC machining is a critical component… transforming raw materials into precisely shaped molds”. Complementary machines like EDM and grinders handle the fine details. In short, a well-equipped mold shop will have state-of-the-art CNC mills, EDMs, grinders, and supporting tools to handle every phase of mold construction.

Supported Materials for Custom Mold Making

Mold Tool Materials: Custom molds themselves are almost always made from durable metals or high-performance alloys. The two most common materials are tool steel and aluminum.

-

Tool Steel: Mold-grade steels (e.g. P20, NAK80, H13, S136) are preferred for high-volume molds. They can withstand millions of injection cycles, high injection pressure, and abrasive materials. Tool steels are wear-resistant and can be polished to a mirror finish. As one source notes, steel molds “will last longer, ensure greater durability” than alternative materials. Hardness and toughness can be tailored via heat treatment. However, steel is expensive and slower to machine (especially hardened grades).

-

Aluminum: For lower-volume or prototype tools, aluminum alloys (like 7075-T6) are often used because they machine much faster. Aluminum molds cost less and can be built quickly, but they wear out sooner. As advanced prototyping experts explain, aluminum is a “cheaper alternative” that still provides high-quality parts in many cases. It’s suitable for runs in the hundreds or low thousands of parts.

-

Copper Alloys: In specific cases, copper alloys such as beryllium-copper are inserted into steel molds at critical spots. Beryllium-copper has exceptional thermal conductivity, speeding up cooling. It can greatly reduce cycle time, though it is more expensive. While not cited above, industry practice uses copper inserts especially around gates or cores that run hot.

-

Soft Tooling Materials: For rapid tooling or very low volumes, softer materials can form molds. Epoxy or polyurethane castings (often made from silicone master molds) can be used to create molds for limited short runs or prototypes. These “soft” molds are inexpensive and quick to produce, but are not long-lasting. The advanced prototype firm APM highlights offering soft prototyping molds when “durability isn’t a concern”.

Molded Part Materials: On the other side, what materials can be shaped by these molds? Virtually any moldable material can be used, depending on the process:

-

Plastics (Thermoplastics & Thermosets): The most common are thermoplastics (like ABS, polypropylene, nylon, polycarbonate, POM, etc.), which are melted and injected. Thermosetting plastics (like phenolic, epoxy) and liquid silicones (LSR) are also molded in custom molds. Industry sources list “thermoplastics, thermosetting polymers, and elastomers” as typical injection mold materials. Rubber compounds and silicone elastomers (for example, automotive seals) require molds designed for flexible materials.

-

Metals (Die Casting): Molds (dies) are also used to shape metal alloys by high-pressure casting. Die-casting dies are custom steel tools that mold molten metal (e.g. aluminum, zinc, magnesium, copper). For instance, auto engine parts might be made in aluminum die-cast molds. The custom mold-making process applies to die casting by using similar design and machining principles, but with special considerations for metal-solidification and high pressures.

-

Other Materials: Molds can form composites (e.g. carbon or glass-filled thermoplastics) and ceramics (e.g. ceramic injection molding). Even food products (chocolate, candy molds) or plaster casting in architecture rely on molds, though typically using softer mold materials.

In summary, custom mold makers build their tools from steel, aluminum or specialized alloys, choosing based on part volume and material. These tools then support a wide range of moldable materials – from everyday plastics and rubbers to die-cast metals – enabling thousands or millions of identical parts.

Manufacturing Processes Using Custom Mold Making

Custom molds are central to many manufacturing processes. Key examples include:

-

Plastic Injection Molding: By far the most common use of custom molds, injection molding feeds molten plastic into a mold cavity under pressure. Once cooled, the precise plastic part is ejected and the cycle repeats. Injection molds can have multiple cavities to produce several parts per cycle. This process is ideal for high-volume production of complex plastic components.

-

Compression Molding: Used mainly for thermoset plastics and rubber. A pre-measured slug of material is placed in an open mold, then the mold closes and heat/pressure force the material to fill the cavity. It’s often used for large, thick or structural parts (e.g. automotive underhood parts, appliance panels). Custom compression molds are engineered with robust construction to handle heavy pressures.

-

Blow Molding: This process creates hollow plastic parts (like bottles or tanks). A heated plastic preform is placed in a two-part mold and then expanded with air pressure to take the mold’s shape. Custom blow molds (usually two-part split molds) are made for each product design and must withstand repeated pneumatic cycles.

-

Rotational Molding (Roto): A mold is slowly rotated (usually biaxially) with plastic powder or resin inside. Heat makes the plastic melt and coat the interior, forming a hollow part. Rotational molds are typically much simpler (often only one or two pieces) because no high pressure is involved. They are used for large hollow parts (kayaks, tanks, playground equipment).

-

Liquid Resin (RTV) & Urethane Casting: For prototyping or short runs, silicone (RTV) molds or urethane-cast molds are used. A master pattern is used to create a silicone mold, which is then used to cast parts in urethane or epoxy. Custom RTV molds replicate the geometry at low cost. While not metal, they follow the mold-making principles of accurately shaping cavities.

-

Vacuum Casting: Often used in prototyping, silicone molds are placed in a vacuum chamber where liquid resin is introduced. This is mentioned as a complementary technique. It produces small batches of plastic parts from molds.

-

Die Casting (Metal Molding): Molten metal (usually aluminum, zinc or magnesium) is injected under high pressure into a custom steel mold (die). The cooled metal part is ejected. Die-casting molds must be very rugged to withstand high temperature and pressure. This process is common for metal housings, engine parts, and electrical hardware.

-

Rubber & Silicone Molding: Specialized injection molds exist for rubber (e.g. liquid silicone rubber or thermoplastic elastomers). These molds are often heated to cure the rubber and may include bubblers or venting for air release.

In practice, any molding process that shapes materials via a rigid cavity relies on a custom mold. Summarizing multiple sources: injection molding (plastics), compression molding (thermosets), blow molding (hollow plastics), vacuum casting (prototype resins) and investment/metal casting (for metals) all use custom tooling. Each process has its own mold design rules, but the underlying concept – a custom-engineered mold as the production tool – is constant.

How Much Does Custom Mold Making Cost?

Custom molds involve significant upfront investment. Typical costs range widely depending on complexity, size, material and quantity of cavities. Industrial sources give ballpark figures: simple single-cavity molds may start around $3,000–$6,000, while large multi-cavity or complicated molds can exceed $100,000. In fact, Formlabs reports that plastic injection molds can vary from as little as $100 (for a crude 3D-printed prototype tool) up to $100,000+ for a complex high-volume steel mold. Another expert note is that industrial-grade molds (especially in the automotive sector) can range anywhere from $15,000 for simple designs to well over $500,000 for very large, complex tool sets.

Key factors driving mold cost are:

-

Part Complexity: Complex shapes, fine details, and tight tolerances require extra machining (more EDM operations, fine polishing, etc.), raising cost. Deep undercuts or sliders add complexity.

-

Number of Cavities: A 4-cavity mold roughly costs more than four times a 1-cavity mold, since each cavity needs its own tooling operations.

-

Mold Size: Larger molds (for big parts or multi-cavity) cost more due to bigger blocks of steel and longer machining times.

-

Material: Steel molds cost more than aluminum prototypes, both in raw material and machining time. Specialty steels (e.g. corrosion-resistant or extra-hard grades) add to expense.

-

Machining Time: More material removal and fine finishing means higher machine hours. Intricate molds might need many EDM electrodes (each machined separately) and more grind/polish steps. Industry guides note that “mold size, complexity, type [and] number of injection cavities” are major cost factors.

-

Volume Requirements: For very large production runs, investing in a fully hardened steel mold with longer service life is justified (albeit at higher cost). For short runs, cheaper soft tooling may suffice.

-

Features: Hot-runner systems (to eliminate runners), conformal cooling channels (for faster cycles), special coatings, and high-precision surface textures all increase cost.

-

Quality Standards: Certifications (ISO, medical, etc.), extensive inspection, and polish quality (Class A mirror vs. matte) also add to tooling expense.

Breaking down a typical cost composition: The raw steel alone may be thousands of dollars; labor (CNC/EDM time) is often the bulk. Some sources break the cost into material + machining + design fees. For example, one company states simple prototype molds can cost ~100 USD, whereas a complex multi-cavity steel mold can reach 100,000 USD. Advance Plastics similarly explains basic molds often run in the low thousands while larger molds with multiple cavities “start at $25,000 and can work their way up”.

Design Considerations for Custom Mold Making

Designing a mold requires careful attention to many details. Key considerations include:

-

Part Design & Draft: Ensure the part has adequate draft angles (taper on vertical walls) to allow ejection. Common guidelines recommend 1–3° draft on most features. Adding draft tapered walls is crucial – it prevents parts from binding in the mold. Sections with flat vertical walls will need slides or collapsible cores if draft can’t be provided. Fillets (rounded corners) are also used to reduce stress concentrations.

-

Wall Thickness and Uniformity: Consistent wall thickness avoids sink marks and warpage. If thickness must vary, incorporate generous radii (no sharp thickness steps). Thinner sections cool faster; design gating or packing strategies accordingly.

-

Gating and Runner System: Determine where the plastic will enter the mold. Gate location affects material flow, weld lines, and cosmetic quality. Gates should be placed to fill the cavity efficiently and avoid high-stress areas on the part. The runner system (cold or hot runners) must balance flow to all cavities. Hot-runner systems eliminate runner waste but add complexity and cost.

-

Venting: Molds must allow air to escape as material fills. Vents (tiny gaps or dedicated vent slots) are needed at the end of fill paths (opposite the gate) to prevent burn marks or incomplete fill. Proper venting is often down an ejector pin or a porous insert, as suggested by design guides.

-

Cooling System: Efficient cooling channels greatly affect cycle time and part quality. Design cooling circuits that are close to heated areas of the cavity and symmetrical. Modern methods include conformal cooling (channels that follow part geometry). A well-cooled mold keeps temperature uniform, reducing cycle time and warpage. Mold makers routinely use mold flow simulation to optimize cooling layout.

-

Ejection System: Plan ejector pins, sleeves, or stripper plates to safely push parts out. Ejector pins leave small round marks, so they are usually placed on non-critical surfaces. Ensure there are enough pins to release the part without distortion. Consider alternate ejection (strippers, air ejection) for delicate or very flat parts.

-

Parting Line: Decide where the mold splits. The parting line is typically along the largest flat or feature in the part. A well-chosen parting line minimizes visible seams on the final part and makes the mold easier to machine.

-

Undercuts and Slides: If the part has undercuts (features that would trap it in the mold), design slides or lifters into the mold. These moving mold inserts can form undercuts but add to tool complexity and cost. The location and mechanism for such slides must be engineered carefully.

-

Tolerances and Finish: Specify critical tolerances and surface finishes on the mold drawing. High-gloss or textured finishes on the plastic part require corresponding mold polishing or texturing. Tight dimensional tolerances (±0.01mm, for example) require more precise machining and inspection.

Relevant Standards:

- ISO 2768(General Tolerance Standard)

- DIN 7168(Machining Dimensional Tolerances)

- GB/T 1804(Chinese Dimensional Tolerance Standard)

-

Material Selection: Choice of mold material (steel grade) should reflect expected mold life and material to be molded. Harder steels for abrasive or glass-filled plastics; corrosion-resistant steels if molding corrosive resins.

-

Simulation and Analysis: Modern mold design almost always uses mold-flow or FEA to predict filling patterns, cooling efficiency, and warpage. Adjusting the design based on simulation results can prevent costly mistakes.

These considerations ensure a mold functions properly. Designers often iterate between the part engineer and mold maker in early stages. In fact, many companies offer a free DFM (Design for Manufacturing) analysis to catch issues like insufficient draft or thick ribs before tooling begins. Incorporating best practices at the design stage reduces trial-and-error later.

For example, academic guidelines emphasize keeping side walls parallel to ease draft and avoiding deep narrow ribs that complicate venting. In summary, good mold design balances the part requirements, manufacturing constraints, and the chosen molding process to achieve a reliable, cost-effective tool.

Common Problems in Custom Mold Making

Despite careful design, several issues can arise during mold making or mold production. Procurement teams should be aware of these common problems:

-

Part Defects: Even with a well-made mold, defects can occur in molded parts. Common defects include warpage (part distortion due to uneven cooling or shrinkage), sink marks (sunken areas where thick sections cooled slower), and flash (excess material along parting lines from incomplete clamping). These defects usually point back to the mold design or process settings (e.g. inadequate cooling balance, insufficient clamp force, poor venting). As industry engineers note, flawed mold or part design, temperature fluctuations, or improper material selection can lead to such imperfections.

-

Short Shots (Incomplete Fill): A short shot occurs when the mold cavity isn’t fully filled (often due to high injection speed without enough pressure or an occlusion). This results in incomplete parts. It can stem from undersized gates, too fast cooling, or trapped air (bad venting).

-

Flow Lines and Weld Lines: Flow lines (visible streaks on the surface) happen when melt front velocities vary. Weld lines occur where two flow fronts meet and do not fuse perfectly, weakening the part. These are usually solvable by adjusting gate location or mold temperature.

-

Material Issues: Moisture in hygroscopic plastics can cause splay (silver streaks) or burns. Contaminants in pellets can cause voids or black specks in parts. Using properly dried and high-quality material is critical.

-

Machining Tolerances: During fabrication, errors in machining can cause misalignment of mold halves, resulting in flash or mismatched parts. Highly precise CNC and EDM are needed; insufficient finishing can leave tool marks or dimensional errors.

-

Mold Wear and Damage: Over time, molds can wear (rounded edges, eroded gate) or become damaged (cracks from high stress, corrosion if moisture). Inadequate maintenance (for example, not cleaning vents, or running abrasive materials without coatings) can shorten mold life. Skilled mold makers often apply surface coatings (like NiP plating) on critical areas to extend life.

-

High Costs and Delays: Complex custom molds are expensive and time-consuming. Underestimating the complexity during quoting or design can lead to cost overruns and schedule slips. Change orders after mold build begins (e.g. part design changes) are particularly costly.

-

Communication Gaps: Because mold making is technical, miscommunication between a buyer and manufacturer about specifications can cause problems. For instance, not clarifying tolerances or surface quality can lead to mismatches between expectations and delivered tooling.

Careful planning, choosing an experienced mold maker, and ongoing quality control can mitigate these issues. Many mold makers (like Huazhi) emphasize upfront DFM analysis and multiple sampling rounds to catch and resolve problems early. By understanding these common challenges, procurement teams can ask the right questions and work with the manufacturer to ensure a smooth project.

Conclusion:

In conclusion, custom mold making is a sophisticated blend of engineering, materials science, and manufacturing. It enables consistent mass production of complex parts by creating precision tools tailored to each design. This article has covered the full scope: from the definition and history of mold making, through the technical steps and equipment involved, to costs, timelines, design tips and common pitfalls. With nearly every modern manufacturing sector relying on custom molds, an informed procurement team can make strategic decisions about design and suppliers.

Why Choose Huazhi for Custom Mold Making

Huazhi Mold emerges as a strong choice for custom mold making. With 20 years of industry experience, Huazhi claims deep expertise in automotive and industrial molds. They offer free DFM analysis to optimize your design for manufacturability and cost. Their process includes strict 16-point quality control from design to delivery and focuses on efficiency: gate locations and cooling channels are engineered to minimize deformation and cycle time. Huazhi also emphasizes competitive pricing, optimizing every step to save up to 20% in overall cost and time for clients.

When you choose Huazhi, you partner with a team that provides consultative design support and thorough project management. Their track record of customized solutions (from automotive intake manifolds to detailed housing molds) demonstrates their capability. In short, Huazhi combines advanced technology, rigorous quality, and customer-focused service to ensure your custom mold meets requirements.

If your next project involves a specialized mold – whether for injection, die casting, or another molding process – Huazhi’s expertise can be invaluable. Their team is ready to guide you from concept to production, ensuring efficient delivery of a high-performance mold. Contact Huazhi today for a quote or consultation and turn your custom mold-making project into a reality.

FAQ

Q: What factors determine the cost of custom mold making?

A: The cost depends on many variables. Key factors include the mold complexity (geometry, number of cavities, undercuts), the material of the mold (steel costs more than aluminum), and the part count/volume (high-volume runs justify higher-quality molds).

Machine time is a big driver: large molds or fine details require more CNC/EDM hours. Additional features like hot runners, special coatings, or very tight tolerances also add cost. In short, a simple prototype mold might be just a few thousand dollars, while a full-production steel mold for high volume can easily exceed six figures.

Q: How long will it take to build my mold?

A: Lead time varies. A single-cavity prototype mold may be delivered in roughly 3–4 weeks. A standard 2–4 cavity production mold often takes 6–12 weeks. Very complex multi-slide or multi-cavity molds can take 3–6 months.

These timelines include design, machining, and try-out. Choosing aluminum for a quick-turn mold or providing complete and clear design data can shorten the timeline. Plan accordingly, since each additional cavity or sliding action adds time.

Q: What materials can be molded with custom molds?

A: Custom molds can process a broad range of materials. In plastics, any typical thermoplastic (ABS, PP, Nylon, PC, etc.) and thermoset (epoxy, phenolic) can be injection molded. Elastomers and liquid silicone (LSR) are also common. For metal parts, die-cast molds allow alloys like aluminum, zinc and magnesium.

Some custom molds are made for rubber, ceramics, or even composites. Essentially, if a material can be cast or injected and cooled in a cavity, it can be handled by a custom mold. The chosen mold design will reflect the material – for example, molds for rubber need venting different from plastic molds.