Home Appliance Mold Solutions

Home appliance mold services to meet your custom needs. We help you design and build molds that boost production efficiency.

Why Choose Huazhi for Home Appliance Mold Services

One-stop Service

Huazhi provides one-stop home appliance mold services, covering everything from product design to injection molding, surface finishing, and final inspection. Our in-house teams ensure that each stage of production is aligned with your exact specifications, maintaining consistent quality and minimizing delays.

Fast Lead Time

Leveraging certified domestic factories and a robust supply chain, we streamline the injection mold tooling process to accelerate your product development cycle, ensuring rapid production of your home appliance injection-molded parts.

Injection Molding Experience

With over a decade of hands-on experience in the injection molding industry, Huazhi excels at designing and producing high-performance home appliance molds. We leverage advanced molding techniques, such as integrating recycled plastics and multi-material combinations, to create stronger, more efficient components tailored for modern appliances.

Our Awesome Clients

Our Home Appliance mold Injection Molding Services

🔹Plastic Product Design for Home Appliances

Our product design process for home appliance mold projects prioritizes safety, aesthetics, and efficiency. We strictly follow recommended safety standards for plastic appliance products while delivering compact, modern, and affordable designs. We tailor every solution to your preferences, ensuring optimal product-market fit.

🔹Professional Home Appliance Mold Design

With a highly experienced design team, Huazhi utilizes advanced CAD software and MoldFlow analysis to develop precise, functional molds for a wide range of home appliances. Our home appliance mold designs are thoroughly analyzed to identify and eliminate potential performance or structural issues before manufacturing begins.

🔹Precision Mold Manufacturing

At Huazhi, every home appliance mold is manufactured using high-precision equipment under strict supervision by seasoned mold engineers. We adhere to rigorous quality control standards throughout the entire process. Each mold undergoes post-production technical inspections to ensure dimensional accuracy and long-term performance.

🔹Efficient Injection Molding Process

Our optimized injection molding processes minimize production costs and lead times without sacrificing quality. Using only high-grade materials from verified suppliers, we ensure that your home appliance components are durable, dimensionally stable, and free from warping or cracking.

Home appliance molds combine different types of molds, such as hot stamping molds, vacuum forming molds, and adsorption molds. Therefore, there is a close relationship between home appliance products and home appliance molds. When producing home appliance molds, expertise in home appliance plastic molding is essential to manufacturing high-quality components. Many companies choose mold manufacturing in China because of its cost-effective solutions and precision. Reliable Chinese mold manufacturers can provide the tools and expertise required for injection molding white appliances, ensuring that the products meet industry standards.

China’s mold manufacturing process is mature, and many companies specialize in the design and production of appliance molds. Whether you are looking for a mold manufacturer in China or seeking mold manufacturing services in China, there are many options to meet your needs. Home appliance plastic injection molding is a key part of the manufacturing process, providing durable and consistent parts for a variety of appliance products.

As a leading home appliance injection molding manufacturer, Huazhi ensures that all injection molded products meet the strict requirements of our customers. We are committed to continuously improving our services and the quality of home appliance molds.

What are the advantages of Huazhi

120+

Advanced Equipment

Introduction the world's leading precision machinery, improving manufacturing capabilities, setting standards for precision and excellence, and providing customers with versatile and high-quality production services.

180+

Technical Staff

Our team covers multiple professional fields from engineering to mold design, quality control and project management, creating comprehensive professional technical capabilities to ensure efficient project completion.

20+

Experience

With more than two decades of accumulated expertise and successful cases, we stay ahead in manufacturing innovation and provide customers with consistently high-quality and reliable products.

30+

Served Countries

Huazhi Mould has established a solid business in more than 30 countries, including the United States, Germany, Japan, the United Kingdom and India, and strictly abides by international standards.

Find High-Quality China Home Appliance Mold Services?

Partner with a trusted expert to reduce lead times and enhance your manufacturing efficiency. Get a free consultation today! Click below to inquire now and let’s create the perfect mold for your needs.

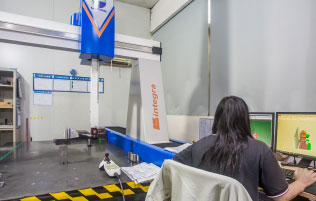

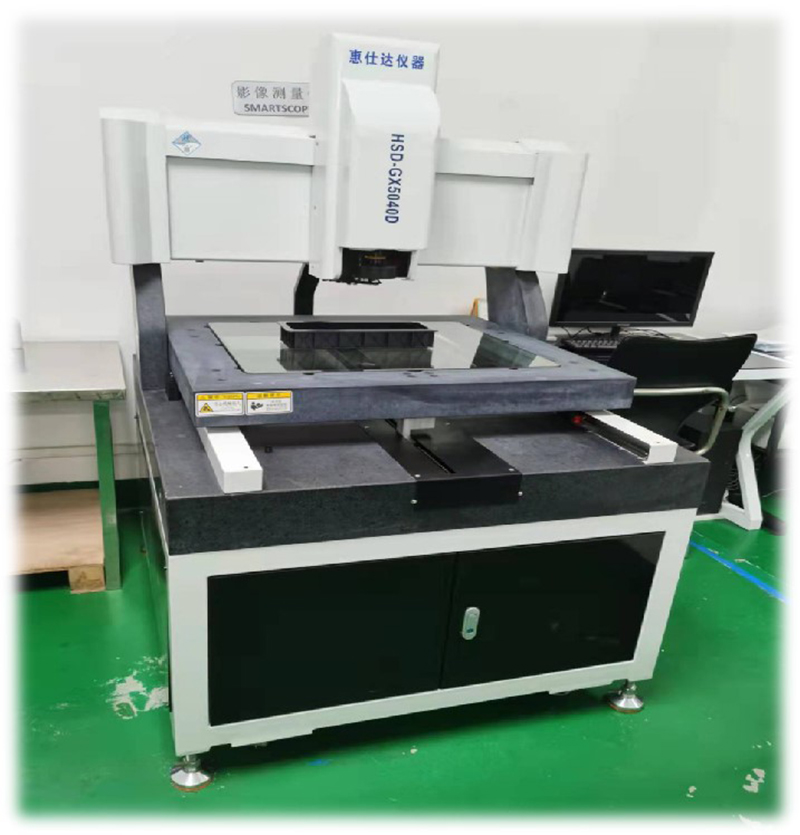

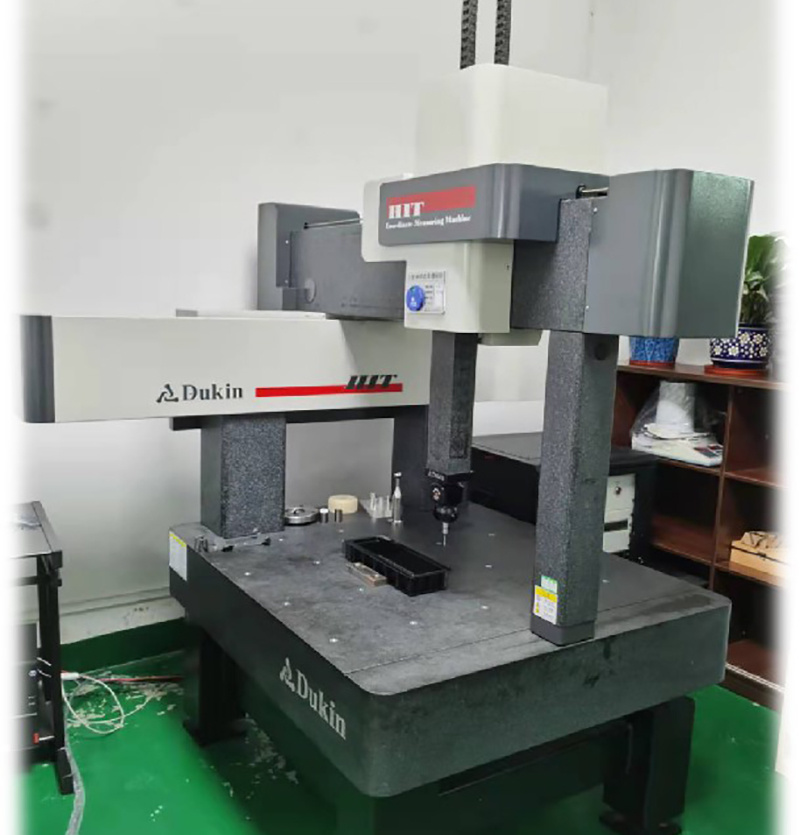

Quality Control Center – Injection Molding Product Inspection

At Huazhi Mould, we ensure the highest precision and quality in every project. Our advanced inspection equipment guarantees strict adherence to specifications throughout the injection molding tool making process. With high-precision CMMs, optical projectors, hardness testers, and other cutting-edge measuring tools, we verify dimensional accuracy, material properties, and mold performance. This rigorous quality control helps us deliver reliable and high-performance molds, optimizing your production efficiency.

How We Build Plastic Injection Molds to Support Your Home Appliance Business

At Huazhi, we are committed to delivering reliable, high-performance home appliance mold solutions. From tailored mold designs to precision machining and expert assembly, our team ensures every mold meets your exact needs—efficiently, accurately, and on time.

Customized Mold Design

Huazhi leverages advanced injection molding software to create precision-designed molds for a wide range of plastic home appliances. Simply provide your product specifications, and we’ll build a home appliance mold tailored to your exact requirements—ensuring optimal form, fit, and function.

Expert Engineering Team

Our engineering team is one of the most experienced in the industry, capable of handling even the most complex custom mold projects. Once your design is confirmed, our engineers will execute your home appliance mold project with maximum efficiency and precision.

Injection Mold Machining

Using our state-of-the-art CNC machines, we ensure high-speed and high-accuracy production of mold components. This allows us to build durable, detail-rich home appliance mold prototypes with excellent consistency, setting the stage for smooth and efficient injection molding.

Mold Finishing & Assembly

We provide comprehensive mold finishing and assembly services to deliver complete, production-ready home appliance mold systems. Our streamlined workflow, combined with years of hands-on experience, guarantees the highest quality results within industry-leading timeframes.

FAQs About Home Appliance Mould

A home appliance Mould is a precision-engineered mold used to manufacture plastic parts for household appliances such as washing machines, refrigerators, microwaves, and air conditioners. These molds ensure high accuracy, durability, and consistency in mass production.

Huazhi specializes in designing and producing all sizes of home appliance mold—from small components like knobs and buttons to large housing parts for washing machines, refrigerators, and more. We can handle both simple and complex multi-cavity molds.

We follow strict ISO 9001 quality management standards, use high-precision CNC equipment, and conduct thorough mold flow analysis. Every home appliance Mould goes through technical inspections and performance testing before delivery.

Yes, our experienced engineers provide full support during the mold design stage. We use advanced CAD/CAM software and MoldFlow analysis to optimize the structure and performance of your home appliance Mould, reducing risk and enhancing product quality.

We select only premium-grade steel and mold base materials from trusted suppliers to ensure mold longevity and stability. Each home appliance Mould is built to withstand high-volume production while maintaining dimensional accuracy.

Typical lead time depends on mold complexity and size. However, thanks to our streamlined workflow and in-house capabilities, Huazhi can deliver standard home appliance Mould projects within 25–45 working days, including mold design, fabrication, and testing.

Quality

Certifications

Huazhi has many patent certificates and strictly implements international quality control standards in production to ensure product quality. It has passed IATF16949, lSO 9001, lSO4001, lSO45001 certifications.

Related Resources

Get a Free Consultation Now

If you have any questions about home appliance mold injection projects, or are looking for a Chinese home appliance mold manufacturer, please contact Zhongshan Huazhi for more information. Our experienced engineering team will provide professional advice and solutions for your home appliance mold injection projects based on your CAD drawings and process diagrams.