Multi Component Injection Molding for Complex Part Designs

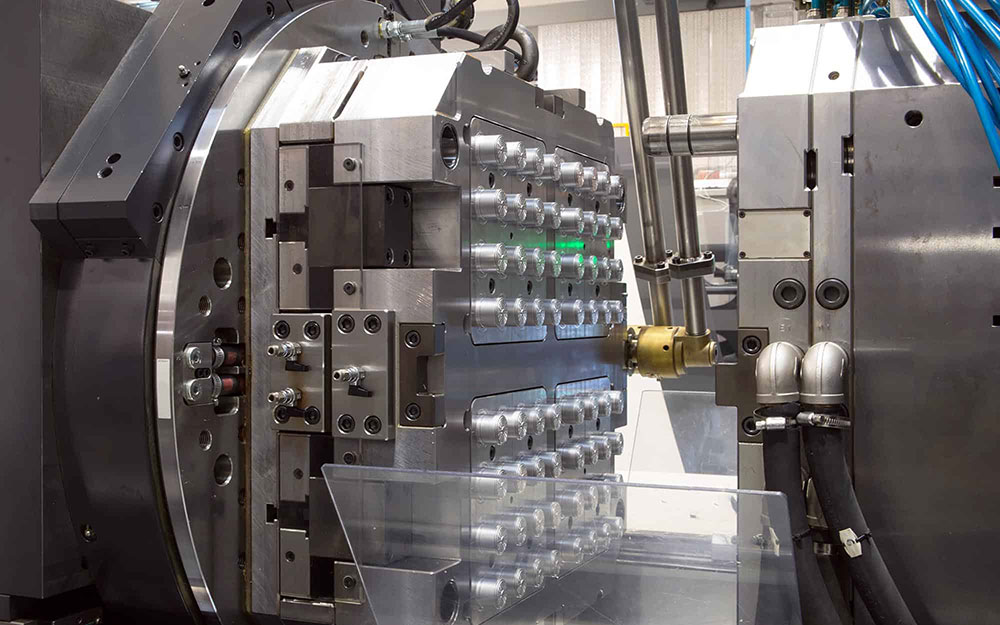

Multi component injection molding uses specialized multi-shot molding machines with two or more injection units to combine different materials or colors in a single production cycle. In this process, plastics (and sometimes elastomers or metals) are injected either simultaneously or sequentially into one mold, creating a unified, multi-material part. The result is an integrated component that leverages the strengths of each material – for example, a rigid plastic base with a soft-touch TPE overmold – without separate assembly steps.

This “multi component” process can produce complex geometries, textured surfaces, and color patterns in one shot, offering design freedom well beyond traditional single-material molding. By molding multiple elements together, manufacturers eliminate secondary assembly, streamline production, and support sophisticated part features that would be difficult or costly to achieve otherwise.

What is Multi Component Injection Molding?

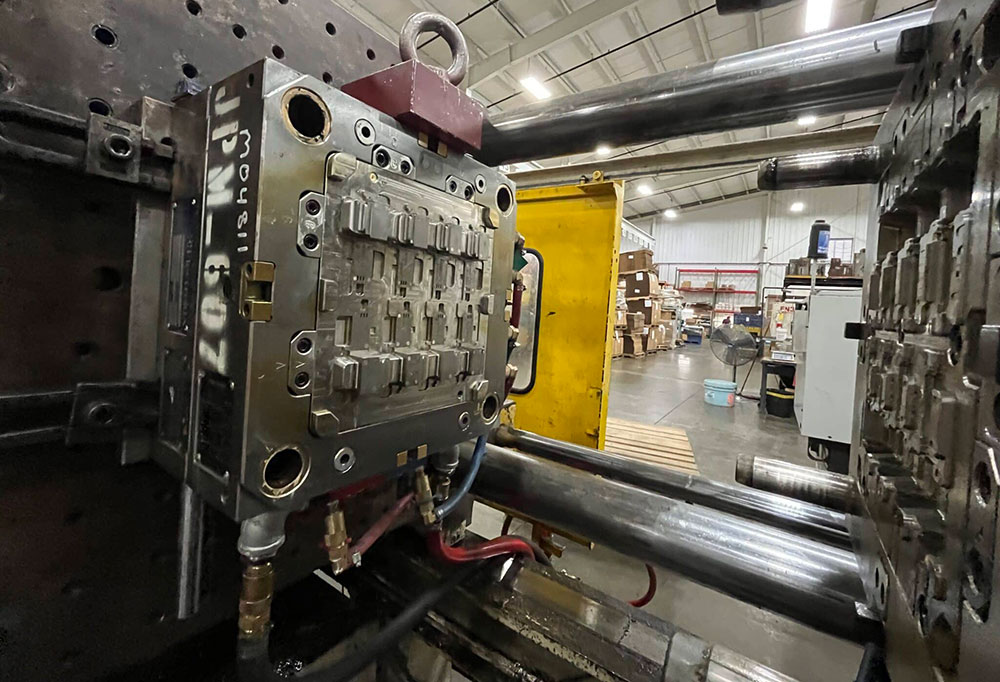

Multi component injection molding (often called multi-shot, two-shot, or multi-material molding) is an advanced plastic molding technique that creates a single part from two or more different polymers or colors in one molding cycle. The core idea is to inject multiple materials into one mold – either at the same time (co-injection) or in sequence (two-shot) – so they bond together within the same tool. In practice, the machine may have multiple barrels feeding the mold or a rotating platen to reposition the part between shots.

For example, a part’s rigid plastic backbone can be molded first, then soft elastomeric sections (like seals or grips) can be injected in a second shot, all without moving the part to a different machine. This process is fully automated and repeatable, making it ideal for high-volume runs. Since the materials bond in-mold, the final multi-material component comes out ready-to-use with no extra assembly.

Advantages of Multi Component Injection Molding for Complex Designs

Multi component injection molding offers numerous benefits, especially for complex part designs and high-performance components. These advantages align well with procurement and manufacturing goals, reducing costs and production steps while enhancing product quality. Key benefits include:

Design Flexibility and Part Complexity

One of the primary strengths of multi component injection molding is design freedom. Combining materials in a single part allows engineers to integrate multiple functions and features into one component. For instance, ergonomic overmolded grips, built-in seals, or snap-fit hinges can be molded directly into a part. As SIMTEC explains, using multiple materials “allows for greater design flexibility to achieve complex part designs, desirable product features, and enhanced product performance”. Unlike single-material parts, multi component molded parts can display different colors, textures, or hardness levels on different areas.

An automotive knob might have a hard plastic core with a soft-touch outer ring, or an electronics housing might have a rigid frame with a rubberized handle molded in. The result is a single-piece assembly that visually and functionally combines multiple materials. In short, multi component injection molding unlocks maximum design freedom – designers are no longer limited to one material’s properties. According to industry sources, this process creates “high-quality multi-colour designs” and “complex moulded parts comprising two or more components,” which drives its adoption in fields requiring both aesthetics and function.

Material Integration and Functional Versatility

Multi component injection molding excels at material integration. Manufacturers can take advantage of the desirable characteristics of each material used, combining them into one part. For example, the rigidity and dimensional stability of a thermoplastic can be paired with the flexibility or sealing properties of an elastomer within one component. This enables parts that incorporate hard plastic supports alongside soft, gripping overmolds or sealing lip features. As SIMTEC notes, “the rigidity of a thermoplastic or weight of a metal mass [can be] combined with the flexibility, sealing, or delicate features of an LSR (liquid silicone rubber)”.

In practice, this means a single part can have areas of differing hardness, elasticity or thermal resistance. Multi component molding also allows multi-color parts without painting or decoration steps – the machine can inject differently colored resins in precise locations, yielding intricate color patterns or logos in-mold. Overall, this versatility helps engineers tailor product properties exactly to the application.

For instance, a consumer tool handle can have a durable plastic core with a soft TPE grip molded over it, or a medical device connector can have a hard body with an integrated silicon seal. The strong intermaterial bonding achieved in the mold often exceeds what can be done with adhesives or mechanical assembly, improving final part durability.

Reduced Assembly and Faster Production

By producing a fully integrated part in one molding cycle, multi component injection molding eliminates the need for secondary assembly. Traditional multi-material products often require separate molding of each component and then labor-intensive bonding (ultrasonic welding, adhesives, press-fitting, etc.). With multi component molding, each functional element is created in place, saving those steps.

This delivers significant time savings and streamlines the manufacturing process. According to industry case studies, integrating multiple elements into one mold yields a “significant savings… in production costs for added assembly or other secondary operation equipment, labor costs for manual operations and material handling, and a time savings”. In other words, manufacturers dramatically cut labor and overhead by turning what used to be multiple workstations into a single automated cell.

In practice, this means lower cycle times and faster time-to-market. Multi shot processes also save floor space and reduce machine setups – a single multi-shot machine takes the place of multiple standard injection presses. The result is a more efficient supply chain: fewer parts to order, fewer suppliers to manage, and fewer risk points. As industry research highlights, multi-component molding requires “fewer production steps and a cleaner, smoother transition of materials,” which “offers a more efficient manufacturing process” with “streamlined” supply chains and “improved quality”.

Cost Savings and Production Efficiency

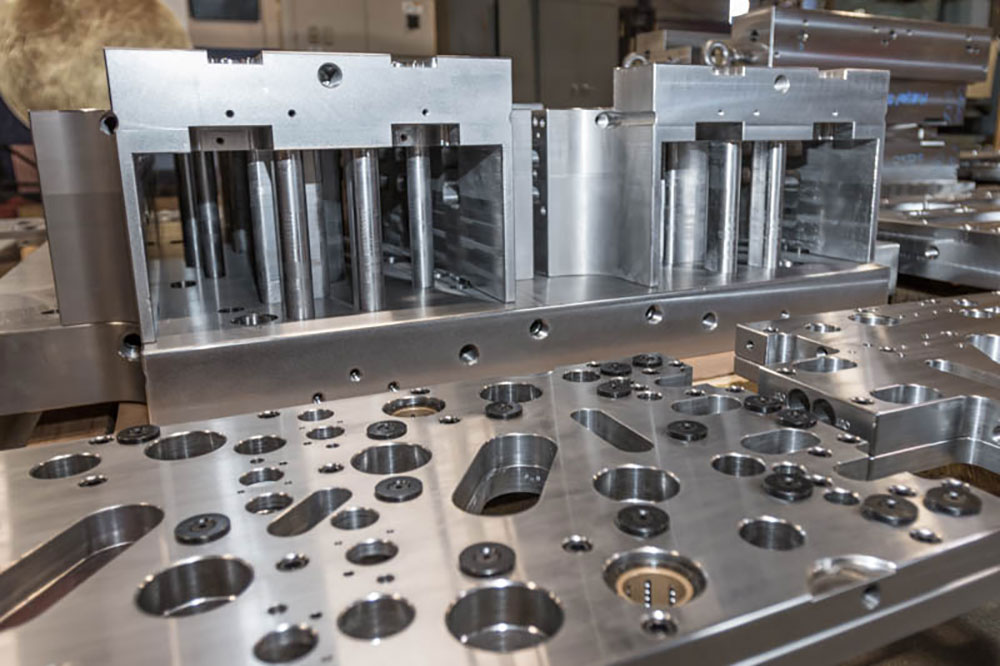

Contrary to some expectations, multi component injection molding can be very cost-effective for complex parts. By combining processes, it lowers overall production cost compared to making separate parts and assembling them. The tooling for multi-component molds is more complex (and thus more expensive) up-front, but the per-part cost drops because only one machine cycle is needed per part. Market studies and industry experts confirm that multi-component molding yields lower overall production costs. The Wikipedia on multi-material injection notes that some key features of this technology are “lower cost” and “significant reduction in assembly operations”.

Likewise, SIMTEC points out that a single integrated cycle eliminates extra equipment and labor for assembly, translating to major cost and time savings. Another consideration is that multi shot machines often use a single mold base with multiple cavities or uses advanced techniques (like cube molds), enabling higher output per machine. For example, Arburg’s cube mold technology can double the number of parts per cycle, effectively increasing output without doubling the mold size.

Combined with shortened cycle times, these efficiencies mean more parts per hour and better use of capital equipment. Procurement teams appreciate that improved efficiency can shave 10–20% off total production cost. In summary, once amortized over high volumes, the advanced tooling and machinery pay off by driving down unit costs and inventory needs.

Improved Quality and Durability

Multi component injection molding often yields higher-quality parts than assemblies of separate pieces. Because the materials are molded in-place, the interface between materials is clean and seamlessly bonded. There are no fasteners or adhesives that might loosen, and the risk of part misalignment is eliminated.

The process is fully controlled and repeatable, ensuring each part meets tight specifications. Skaza notes that multi-material molding is “exact and fully controllable,” enabling “the same excellent results every single time”. The Wikipedia on multi-material molding also lists “higher-quality product” as a key benefit. This means better cosmetic finish (fewer defects) and better functional performance.

For example, overmolded seals and grips are bonded at a molecular level to the substrate, preventing issues like delamination or leaks that can occur with post-assembly seals. Parts can be produced with tighter tolerances and less variation, as there are fewer handling steps. In addition, combining optimized materials can improve overall part performance – for instance, embedding a rigid frame into a soft cup provides structural support and resilience in one shot.

Multi-component molding also improves product reliability by minimizing manual intervention; fewer manual steps mean less chance for errors or contamination. All these factors lead to durable, consistent parts that meet high standards for safety-critical or performance-critical applications.

Applications of Multi Component Injection Molding

Multi component injection molding is widely used across industries that demand complex, high-performance plastic parts. Major applications include:

-

Automotive Components: Complex interior and exterior parts often use two-shot molding. Examples are soft-touch dashboard panels, multi-color trim, integrated seals for fluid systems, and overmolded grips on shift knobs or handles. The automotive industry values multi-component parts for their aesthetics and functionality.

-

Consumer Electronics & Appliances: Products like kitchen appliances, power tools, and electronics housings frequently use multi-material injection. A consumer product might have a rigid plastic body with rubberized buttons or grips integrated during molding. Multi-shot molding is also used for multi-color or translucent visual effects on gadgets.

-

Medical Devices: Many medical products combine rigid and soft materials (e.g. a hard syringe barrel with a soft rubber plunger tip). Multi shot molding enables these in one piece, ensuring sterile, leak-free seals and ergonomic interfaces. Medical connectors and surgical instrument parts often leverage 2K molding for biocompatible materials and tight tolerances. The technology’s precision and cleanliness make it ideal for this sector.

-

Industrial & Power Tools: Ergonomic tool handles, levers, and housings use overmolded grips and seals. For example, a power tool handle can be molded with a hard plastic inner structure and a soft overmold, eliminating assembly of separate grip panels. Similarly, gaskets and flexible joints can be molded in place in industrial components.

-

Consumer Products & Packaging: Smaller goods like toothbrushes, razors, containers, and packaging often use multi-component molding to add color bands, soft finger grips, or multi-material lids. In the packaging industry, multi-layer parts like spouts and caps are produced with advanced multi-shot molds for both functionality and branding.

These examples show that any application requiring multiple materials, colors or built-in features can benefit. Industry analyses note that multi-component molding is “rapidly adopted” wherever product complexity and quality are priorities, from automotive and electronics to consumer and medical sectors. In many cases, multi-component parts are used in place of separate assemblies, improving performance while reducing supply chain complexity.

Why Choose Huazhi for Multi Component Injection Molding

Huazhi Mould offers comprehensive expertise and services to deliver high-quality multi component injection molding solutions for complex part designs. Our strengths include:

-

Extensive Industry Experience: Over 20 years of injection mold manufacturing and plastic part expertise (including more than 15 years in automotive molding) means we understand demanding requirements.

-

Advanced Certifications & Quality: We hold IATF16949, ISO9001 and ISO45001 certifications and maintain a strict quality management system, ensuring consistent precision. Our facilities have a proven zero-recall record on safety-critical parts.

-

Full-Service Capability: Huazhi provides a one-stop solution – from concept and DFM (design-for-manufacturing) analysis to mold design, tooling, injection molding, and secondary operations. Our free DFM consultations help optimize your design for complex multi-material molds. We can also handle assembly and packaging if needed, greatly simplifying your supply chain.

-

Fast Turnaround: We deliver rapid prototyping and tooling. Our mold manufacturing can start within weeks (as little as 3 weeks for raw mold construction) so you can test parts quickly. Faster cycles at the mold stage translate to faster product launches.

-

Experienced Team & Project Management: A skilled team of 180+ engineers and project managers guides every project. We assign dedicated PMs to ensure smooth communication, on-time execution and transparency throughout the process.

-

Cost Savings: By optimizing design and production, we help clients save up to 20% in overall costs. Integrating services under one roof and offering competitive pricing further reduces your investment.

-

Flexible Production: Huazhi can accommodate any volume. We can produce prototype samples from a single piece (no MOQ for samples) and scale up to full production. We also offer multi-shot and overmolding capabilities (including 2K injection and overmold lines) to support complex color and material combinations.

Choosing Huazhi means partnering with a mold maker who deeply understands multi-component molding challenges and solutions. We have successfully delivered complex multi-material mold solutions for automotive, home appliance, medical, and other sectors. Our competitive lead times, strict quality controls, and engineering support make us well-suited to execute your complex part designs reliably and affordably.

Conclusion

In summary, multi component injection molding unlocks powerful advantages for complex part designs by merging multiple materials into one integrated component. This technology offers unmatched design flexibility, cost and assembly savings, and enhanced product quality – all critical factors for procurement teams and manufacturers. By choosing Huazhi as your partner, you gain over two decades of molding expertise, comprehensive support from design through delivery, and proven capabilities in multi-shot injection. We help you realize intricate, high-performance products faster and more economically.

Ready to leverage multi component injection molding for your next project? Contact Huazhi today to discuss your complex part requirements. Our team will work with you to optimize your design, build advanced molds, and deliver high-quality multi-material parts that meet your specifications and budget. Let Huazhi’s expertise streamline your manufacturing and bring your most ambitious designs to life.

FAQs: Multi Component Injection Molding

Q: What is multi component injection molding and how does it work?

A: Multi component injection molding (also known as multi-shot or two-shot molding) is a process where two or more different materials are injected into one mold to form a single part. One material is molded first, then additional materials are injected into the same part within the same cycle.

The result is a fully integrated component combining multiple materials or colors. This eliminates separate assembly because, for example, a hard plastic base and a soft elastomer seal or grip are bonded together in-mold.

Q: What are the main benefits of using multi component injection molding for complex parts?

A: The main benefits include greater design flexibility (complex shapes, colors and textures in one part), integrated functionality (e.g. combining rigid and soft areas), and reduced part count. It also saves cost and time by eliminating assembly steps, improves product quality through stronger bonds and tighter tolerances, and accelerates production lead times since the part comes out of the mold finished. Overall, it lets you create higher-value parts more efficiently.

Q: Which materials can be used in multi component injection molding?

A: A wide range of polymers can be combined, including different thermoplastics (e.g. ABS, PC, PP) and thermoplastic elastomers (TPE). Two common scenarios are: a rigid plastic (like PC/ABS) combined with a softer elastomer (like TPE or LSR) for soft-touch handles or seals, or two plastics of different colors or properties.

In some cases, even metal inserts or filler materials are placed in the mold before injection. Huazhi’s lines support many combinations – for example, our two-shot machines handle PC/ABS + TPE overmolds. The key is material compatibility; we help select materials that bond well together for the best adhesion and performance.

Q: What are typical lead times and costs for multi component injection molding?

A: Lead times depend on design complexity and order size. Generally, mold design and fabrication take longer than for single-material molds due to added complexity. Huazhi can often deliver prototype parts within a few weeks and complete mold builds in roughly 4–6 weeks. Production cycle times per part may be slightly longer than single-shot due to multiple injections, but this is offset by eliminating extra assembly.

Upfront costs (tooling and machine time) are higher, because the multi-shot mold is more complex. However, these are offset by downstream savings – less assembly labor, fewer machines, and higher throughput. In practice, customers often see an overall cost reduction compared to making and assembling separate parts. Huazhi’s competitive pricing and experience also help keep total project costs down.

Q: Is multi component injection molding suitable for small production runs or just high volumes?

A: It can be used for medium to high volumes where amortizing the tooling is worthwhile. The sophisticated molds mean higher initial investment, so very small runs may not justify it. However, for products that will have ongoing demand, multi-component molding is advantageous even at moderate volumes because the per-part cost and assembly savings kick in quickly.

Huazhi is flexible – we can build small multi-component molds for proof-of-concept and prototype phases, and we can start production with low quantities (even a single prototype sample, as we have no MOQ for samples). But the biggest cost benefits come with larger runs where our integrated process dramatically lowers labor and assembly.

Q: How does multi component injection molding improve part quality?

A: Because materials bond inside the mold, multi component parts have seamless interfaces with no assembly gaps or adhesives. This leads to stronger inter-material bonds and more precise alignments. The fully automated process ensures consistent material placement, reducing human error.

According to sources, multi-material injection molding is “exact and fully controllable,” enabling identical results each cycle. Also, by integrating things like seals in-mold, leak or displacement issues from manually assembled seals are avoided. Overall, parts are more durable and uniform.

Q: How do I choose a supplier for multi component injection molding?

A: Look for an experienced partner who has specialized multi-shot molding machines and a track record in complex projects. Important factors include tooling capability (multi-shot molds are complex), material expertise, quality systems, and support services. For example, Huazhi offers free DFM analysis and an engineering team to optimize your part for molding. We have advanced equipment (including turntable and cube molds) and dedicated two-shot molding lines.

Quality certifications like IATF16949/ISO9001 (which we have) indicate strong processes. Also consider capacity and responsiveness – Huazhi handles all mold making in-house and has project managers to keep schedules on track. Finally, review case studies or ask for prototypes – a capable supplier will provide technical feedback and sample runs to ensure your part succeeds.